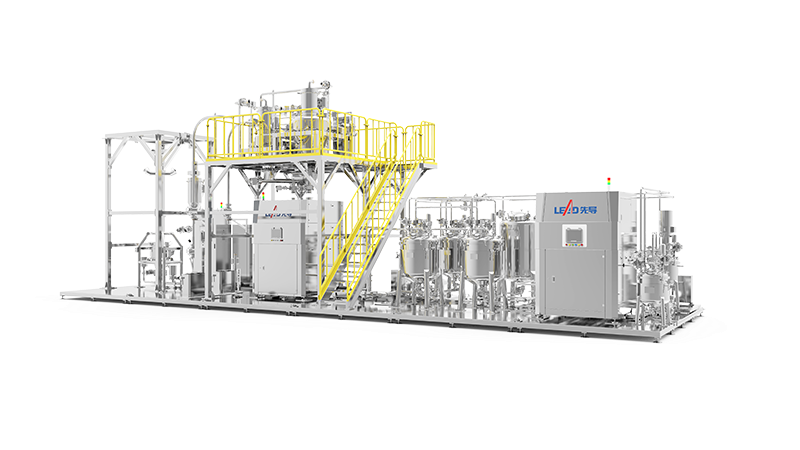

In response to the increasing need for safe, high-performance energy storage, LEAD intelligent has developed cutting-edge machinery for producing all-solid-state batteries. Production lines for solid-state batteries are being revolutionized by LEAD Intelligent, which places a premium on process safety, material compatibility, and simplicity.

Dry Electrode Processing Reduces Investment

One of the key breakthroughs in LEAD Intelligent’s all solid state battery manufacturing equipment is the adoption of the dry electrode process. This eliminates the need for solvents and drying systems, reducing overall investment costs by up to 30%. It also aligns with sustainability goals by cutting down energy consumption during manufacturing.

Streamlined Production with Lower Labor Demand

Solid-state batteries require precision, but LEAD’s systems simplify the steps. The company’s all solid state battery manufacturing equipment is designed to reduce process complexity significantly—cutting labor demand by approximately 20%. This makes it ideal for manufacturers looking to scale production while maintaining lean operations.

Built for Material-Specific Demands

Solid-state battery materials behave differently than conventional lithium-ion components. LEAD Intelligent’s solution adapts seamlessly to these characteristics, improving overall product consistency and safety. From electrode stacking to lamination, every part of the process is fine-tuned for reliability.

Conclusion

LEAD Intelligent’s all solid state battery manufacturing equipment offers a complete solution for battery companies aiming to produce safer, more efficient solid-state batteries. With reduced cost, labor, and complexity, it’s a leap forward in both production capability and technological readiness.