In the manufacturing sector, material accuracy and streamlined processes are vital for consistent production results. PassionIOT has built a reputation for delivering practical systems that address real challenges in electronics and semiconductor operations. Their focus on automation and precision allows manufacturers to adopt advanced methods such as automate label solutions and intelligent counting technologies that ensure reliability across production stages.

Streamlined Labeling and Tracking

Efficient labeling has a direct impact on traceability, quality control, and inventory flow. With their automate label solutions, PassionIOT helps businesses minimize manual intervention while maintaining accuracy in product identification. These solutions are particularly valuable in environments where electronic components or semiconductor parts must be carefully tracked through each step of production. By automating this process, companies gain better oversight, reduce errors, and support smoother transitions between warehousing and assembly.

Precision with X-Ray Counting Systems

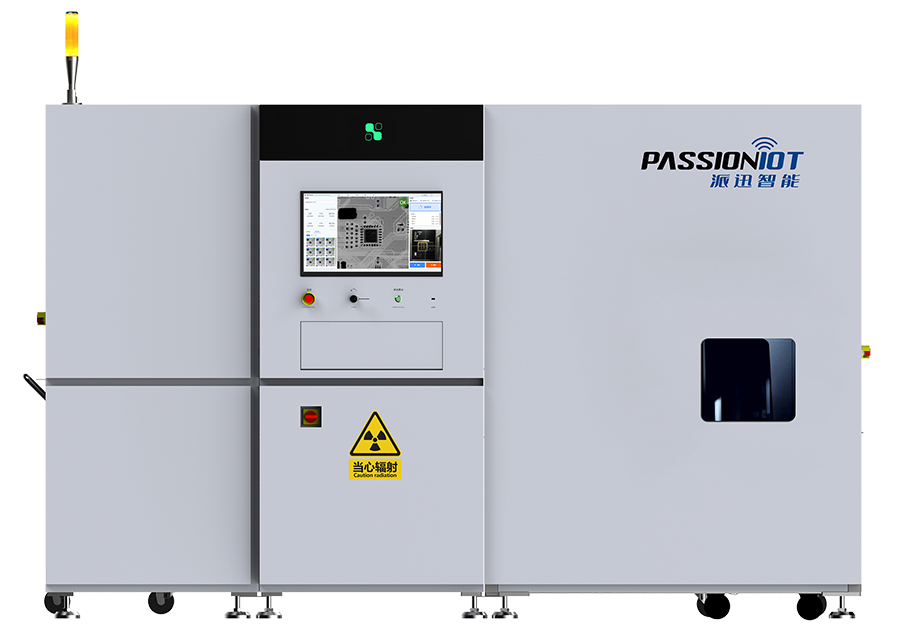

Component management has always been a challenge in electronics manufacturing. To address this, PassionIOT integrates technologies such as the x ray component counter into their intelligent warehouse systems. This equipment uses imaging to quickly and accurately confirm component quantities without requiring reels or packages to be opened. For environments handling high volumes of parts, their x ray smd component counter provides the accuracy needed to ensure that materials match production schedules. This combination of automation and visibility reduces downtime and supports higher consistency in supply chain operations.

Conclusion

As manufacturers adapt to increasing complexity, PassionIOT continues to offer tools that merge automation and precision. Through solutions such as automate label solutions, as well as advanced counting technologies like the x ray component counter and the x ray smd component counter, they provide valuable support for electronics and semiconductor companies. By implementing these systems, businesses can achieve stronger material control and improved efficiency, ensuring processes remain both stable and scalable.